Utilizing AI for Efficient Infrastructure Management Solutions

Outline:

– Why AI matters now for infrastructure, what “learning infrastructure” means, and how this article is structured.

– Predictive maintenance and asset health: data, models, workflows, and measurable outcomes.

– Intelligent operations: optimization of energy, transport, water, and compute resources.

– Resilience and monitoring: computer vision, remote sensing, cyber-physical vigilance, and digital twins.

– Governance and a step-by-step implementation roadmap, including metrics, ethics, and change management.

From Static Systems to Learning Infrastructure: Why AI Matters (and the Roadmap You’ll Follow)

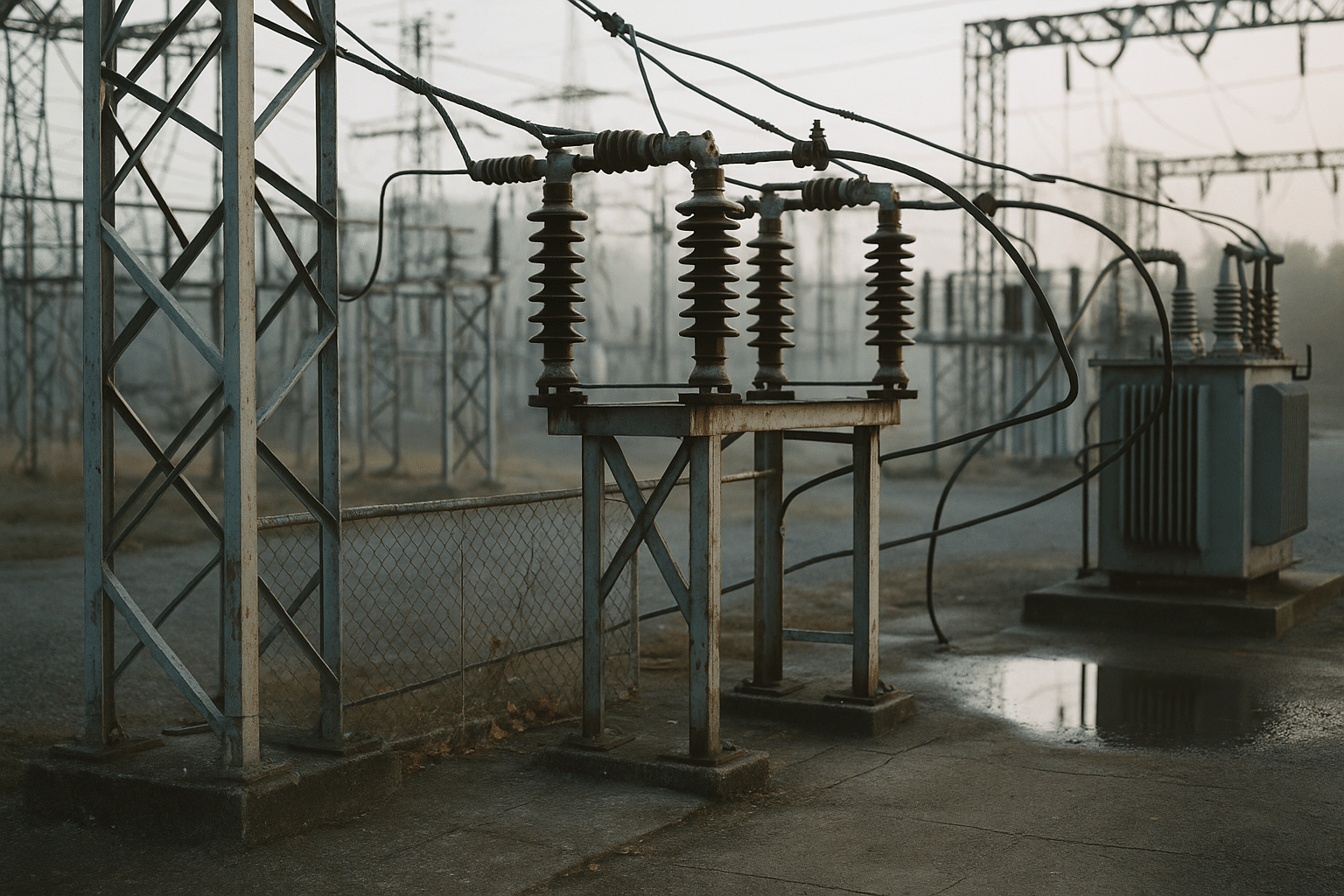

Infrastructure has always been the quiet backbone of modern life—power humming through lines, water flowing beneath streets, packets routing across networks. What has changed is the sheer volume and velocity of data now streaming from assets: vibration from pumps, thermal signatures from transformers, lidar scans from bridges, and logs from servers. Artificial intelligence transforms that raw stream into actionable foresight, so operators shift from reacting to crises toward orchestrating performance. The result is a system that adapts to demand, anticipates wear, and negotiates constraints with nuance that fixed rules rarely match.

Think of three layers: sensing, inference, and action. Sensing captures reality with IoT devices, SCADA feeds, satellite pixels, and maintenance records. Inference applies machine learning to estimate remaining useful life, detect anomalies, and forecast loads. Action pushes decisions into scheduling, control setpoints, and work orders. Compared to purely rule-based automation, learning systems evolve with new data, detect subtle patterns across thousands of signals, and recalibrate as equipment ages or usage shifts. In practical terms, various industry surveys indicate organizations see maintenance cost reductions on the order of 10–30% and downtime cut by double-digit percentages when predictive methods are deployed thoughtfully.

Two architectural choices shape outcomes. First, edge versus cloud: pushing models to the edge shrinks latency for safety-critical actions—opening a valve, tripping a breaker—while cloud aggregation provides fleet-wide insights and more robust training. Second, centralized versus federated learning: centralized approaches simplify governance, while federated schemes let sites learn locally and share only model updates, supporting privacy and bandwidth efficiency. The good news is that both paths can coexist; many teams use an edge-cloud split where fast control loops run locally and strategic optimization runs centrally.

Here is how the rest of the article unfolds to help you build a plan that is both ambitious and grounded:

– Predictive maintenance and asset health: where to start, what data matters, and how to close the loop from model to wrench.

– Operations and optimization: turning forecasts into efficient schedules across energy, transport, water, and compute.

– Resilience and monitoring: seeing faults early, reducing inspection overhead, and managing cyber-physical risks.

– Governance and roadmap: standards, ethics, procurement, change management, and the metrics that actually move budgets.

Predictive Maintenance and Asset Health: From Sensors to Decisions That Stick

Predictive maintenance is often the first AI win because it links directly to uptime and safety. The workflow is straightforward in concept: collect signals, engineer features, train models to estimate remaining useful life or anomalous behavior, and then trigger timely interventions. In practice, success hinges on the quality and diversity of signals, the alignment of predictions with maintenance windows, and the discipline to measure outcomes. Assets that benefit include rotating machinery, transformers, pumps, HVAC plants, track systems, and server clusters where temperature, vibration, or error logs tell rich stories about impending issues.

Data and models you are likely to use:

– Time-series sensing: vibration, acoustic emission, temperature, current/voltage, pressure, flow, log events.

– Feature extraction: spectral features, envelope statistics, trend slopes, co‑occurrence of events.

– Models: gradient boosting, random forests, temporal convolutional networks, recurrent architectures, and physics-informed hybrids for components with well-understood failure modes.

– Outputs: health scores, probability of failure within a horizon, and prescriptive actions tied to parts and skill sets.

Organizations often report results such as 10–40% maintenance cost reduction, 20–50% reduction in unplanned downtime, and higher spare-part availability through improved planning. Those ranges depend on the baseline, asset criticality, and how well scheduling constraints are honored. A model that perfectly predicts a bearing failure is not valuable if the plant cannot secure a work window or the part is on backorder; therefore, predictive maintenance must connect to inventory, labor planning, and permit processes. Closing that loop often yields the largest gains, because it converts foresight into frictionless work execution.

Consider examples across domains. In energy distribution, thermal and load data highlight transformers trending toward overload, allowing reconfiguration or targeted cooling before insulation degrades. In water networks, pressure transients combined with acoustic data spot leak precursors, guiding low-impact night repairs. In rail and road infrastructure, computer vision flags spalling, ballast issues, or surface cracks, prioritizing inspection routes. In data centers, log anomaly models anticipate service degradation, enabling graceful failover and right-sized capacity. Across these cases, the comparative advantage of learning systems over fixed thresholds is adaptability: models incorporate context like seasonal demand, ambient temperature, and asset age, whereas thresholds often treat every Tuesday in July like every Tuesday in January.

To keep models honest, track a small set of metrics:

– Precision/recall on failure alerts, calibrated to risk tolerance.

– Lead time (how far in advance failures are signaled) and how often that lead time is actionable.

– Intervention impact: changes in mean time between failures and work order duration.

– Economic value: avoided downtime cost, parts optimization, reduced overtime, and safety incidents averted.

Intelligent Operations: Optimizing Energy, Transport, Water, and Compute

If predictive maintenance is about avoiding surprises, intelligent operations is about squeezing more performance from the same assets. AI shines where the system space is too large for manual tuning: coordinating traffic signals across corridors, balancing energy loads under variable renewables, controlling pressure in district heating or water networks, and allocating compute across clusters while keeping latency in check. Here, forecasting meets optimization. Short-term demand forecasts shape schedules; optimization models translate forecasts into setpoints, routes, and resource allocations that honor constraints like safety margins and service-level agreements.

Evidence from pilots and scaled programs offers a consistent pattern. In transport networks, adaptive signal control informed by reinforcement learning or robust heuristics has delivered corridor travel time reductions on the order of 10–20% and fewer stops at intersections. In electric systems, smart dispatch that blends storage, flexible loads, and price signals often yields 5–15% peak reduction and measurable improvements in renewable utilization. In water distribution, dynamic pump scheduling guided by predictions of demand and reservoir levels cuts energy use while maintaining pressure bands, sometimes lowering operating costs by high single digits. In compute infrastructure, autoscaling policies driven by workload classifiers reduce idle capacity without compromising performance targets, especially when paired with right-sizing recommendations.

Choosing the right tool matters:

– Forecasting: gradient boosting and temporal deep learning perform well for short-term load, flow, or traffic forecasts; probabilistic outputs help quantify risk.

– Optimization: mixed-integer programming guarantees optimality for small to medium problems; metaheuristics and reinforcement learning scale to larger networks with good solutions under time limits.

– Control: model predictive control bridges forecasts and actuators, enforcing constraints and smoothing actions.

Edge versus center again becomes a design choice. For traffic and industrial controls, decisions within seconds favor edge inference to avoid latency penalties. For day-ahead energy and water scheduling, central platforms can digest more scenarios and compute robust plans. A hybrid approach—edge for real-time guardrails, center for strategic coordination—delivers resilience when communications falter. Importantly, these systems must be human-centered. Operators need intuitive visualizations, override controls, and transparent explanations of why a particular green phase was extended or a pump was slowed. Teams that invest in operator trust typically see faster adoption and more stable performance because human insight catches corner cases models miss.

Finally, do not overlook the quiet gains: smoother operations reduce mechanical stress, which compounds with predictive maintenance to extend asset life. Lower variance in workloads reduces both energy cost and emissions. This is where AI moves from a point solution to a compounding efficiency engine across the portfolio.

Resilience, Safety, and Continuous Monitoring in the Real World

Resilience is the discipline of staying safe under stress—storms, surges, cyber events, or just the wear and tear of time. AI enhances resilience by compressing the time between an incipient fault and a confident response. Computer vision scans surfaces for cracks, corrosion, fretting, or vegetation encroachment; remote sensing identifies ground movement or flood exposure; time-series anomaly detection watches for patterns that correlate with instability; and graph-based analytics map cascading risks across interconnected assets. The goal is early, reliable detection with a minimal false-alarm tax on busy teams.

Field results show significant efficiency gains. Vision-based inspections from ground cameras, drones, or fixed installations can reduce manual inspection hours by 50–80% for assets like bridges, towers, and pipelines, while improving coverage in hard-to-reach locations. In storm seasons, flood modeling integrated with near-real-time precipitation feeds helps pre-position crews and materials, trimming restoration times. Satellite imagery has matured enough for change detection that flags erosion or landslide risk along corridors, helping prioritize preventive work. In operational technology networks, behavior models detect unusual command patterns or device communications that suggest misconfiguration or malicious activity, shrinking time-to-detect from days to minutes in well-instrumented environments.

To make monitoring actionable, pair detection with triage and playbooks:

– Severity scoring that blends model confidence, asset criticality, and proximity to sensitive zones.

– Automated work orders with location, required skills, and safety notes.

– Event correlation that groups related alerts across sensors to avoid alert storms.

Digital twins add context by simulating how faults propagate under varying loads and weather, which supports “what-if” planning. A twin is only as useful as its data freshness, so invest in streaming integration and a cadence for validating model fidelity. Calibration against measured outcomes prevents drift that erodes trust. Equally important are guardrails: rate-limit automated actions, log all decisions, and provide clear handoffs to humans during ambiguous events. Precision and recall must be tuned to the operational reality; a water utility may accept a few extra leak investigations to avoid missed events, while a high-throughput data center might prioritize precision to protect operator bandwidth.

Risks do exist—false positives, model bias tied to sensor placement, and evolving threats that outpace training data. Mitigation strategies include regular backtesting, red-teaming for cyber scenarios, and diversified sensing to reduce single points of failure. With those practices, organizations can build a nervous system that notices trouble early and responds with poise.

Governance, Ethics, and a Practical Roadmap from Pilot to Portfolio

Sustained value from AI in infrastructure depends less on a clever model than on governance, process, and people. A pragmatic roadmap starts small, proves value, and scales with discipline. Begin with a portfolio scan to rank use cases by economic impact, data availability, and operational fit. Pair each candidate with a clear success metric—avoided downtime, energy intensity reduction, travel time reliability, non-revenue water reduction—and a baseline. Then outline the data plan: what sensors are needed, what historical data can be cleaned and labeled, and what quality checks will run in production.

Implementation steps that repeatedly prove effective:

– Architecture: define an edge-cloud split, streaming pipeline, and secure data zones for sensitive operational technology.

– MLOps: version datasets, models, and features; automate training, deployment, monitoring, and rollback; track model drift and data drift separately.

– Human-in-the-loop: incorporate operator feedback on alert quality and usability into model retraining; schedule periodic reviews to prune unused features or dashboards.

– Interoperability: prefer open protocols and data schemas so sites can share components; avoid vendor lock-in by separating data, models, and orchestration layers.

– Security and safety: segment networks, enforce least privilege, and include fail-safe states for automated controls.

Ethical and regulatory guardrails deserve upfront attention. Use privacy-preserving techniques for personally identifiable information in mobility datasets; document model limitations and failure modes; and establish processes for challenging and correcting automated decisions. Transparency is not only an ethical stance—it also reduces onboarding friction for operators and auditors. For risk-sensitive domains, consider interpretable models or post-hoc explainers that articulate which signals drove a decision. Periodic bias and performance audits help ensure equitable service levels across neighborhoods or customer segments.

When it comes to financing and scaling, build a business case that accounts for full lifecycle value:

– Costs: sensors and retrofits, connectivity, storage/compute, integration, training, and change management.

– Benefits: avoided failures, energy savings, extended asset life, crew productivity, compliance efficiencies, and safety gains.

– Timing: many programs see payback between one and three years, with compounding returns as models and processes mature.

Finally, pilot with intention. Select two or three sites that represent different operating conditions, agree on a fixed timeline and KPIs, and plan the “last mile” into work management systems before the pilot starts. Share outcomes widely—both wins and lessons—so adoption accelerates without hype. The through line is simple: pick problems that matter, measure relentlessly, and design for people, not just algorithms. Do that, and AI becomes a reliable partner in the long, careful work of building infrastructure that is efficient, resilient, and ready for tomorrow.